|

Sunday, November 5, 2006

Wednesday, October 4, 2006

Kidney Stonesapple Cider Vinegar And Coconut Oil

Hello,

First of all, thank you for visiting our blog and for your interest in the construction of mass stoves.

As you may have noticed, the early stages of building were chained very quickly, and since the updates are slow in coming. This has a simple explanation: we were on vacation and do not have more! Not easy to continue to keep pace while working the week ...!

However, construction continues to move even more slowly, and we will not forget to update this blog as and when significant advancements ... With of course, first impressions of operation ...!

Happy reading!

Wednesday, September 13, 2006

Psoriasis More Condition_symptoms

achieving

's go for the first layer which is a solid layer of bricks. Previously, we have arranged the bricks on the ground, I do not know if it was a good idea, it's true that it is not easy to be straight and steady ...

's go for the first layer which is a solid layer of bricks. Previously, we have arranged the bricks on the ground, I do not know if it was a good idea, it's true that it is not easy to be straight and steady ...

2nd layer: it starts to have the techique! Must put a lot of mortar, brick and tap with hammer to create a suction effect that "glue" brick really well and spread the mortar underneath. Then, go over the outer seal to ensure water resistance.

2nd layer: it starts to have the techique! Must put a lot of mortar, brick and tap with hammer to create a suction effect that "glue" brick really well and spread the mortar underneath. Then, go over the outer seal to ensure water resistance.

planks on the sides are very useful to try to climb a wall right!

3rd layer: this is it cuts commmencent! It forms the beginning of the flue which passes around the ash box. The flue will be by the left (non-ideal configuration relative to an exit from the rear, but that suits us not to too much beyond the stove in our fireplace).

3rd layer: this is it cuts commmencent! It forms the beginning of the flue which passes around the ash box. The flue will be by the left (non-ideal configuration relative to an exit from the rear, but that suits us not to too much beyond the stove in our fireplace).

's go for the first layer which is a solid layer of bricks. Previously, we have arranged the bricks on the ground, I do not know if it was a good idea, it's true that it is not easy to be straight and steady ...

's go for the first layer which is a solid layer of bricks. Previously, we have arranged the bricks on the ground, I do not know if it was a good idea, it's true that it is not easy to be straight and steady ...  2nd layer: it starts to have the techique! Must put a lot of mortar, brick and tap with hammer to create a suction effect that "glue" brick really well and spread the mortar underneath. Then, go over the outer seal to ensure water resistance.

2nd layer: it starts to have the techique! Must put a lot of mortar, brick and tap with hammer to create a suction effect that "glue" brick really well and spread the mortar underneath. Then, go over the outer seal to ensure water resistance. planks on the sides are very useful to try to climb a wall right!

3rd layer: this is it cuts commmencent! It forms the beginning of the flue which passes around the ash box. The flue will be by the left (non-ideal configuration relative to an exit from the rear, but that suits us not to too much beyond the stove in our fireplace).

3rd layer: this is it cuts commmencent! It forms the beginning of the flue which passes around the ash box. The flue will be by the left (non-ideal configuration relative to an exit from the rear, but that suits us not to too much beyond the stove in our fireplace). Peter Grimm And Washington, Dc And Realtor

Overview before the start of construction:

First and foremost, we removed the stones which formed the floor of the fireplace and were broken in order to run a mini-concrete slab armed ensure stability of the stove.

First and foremost, we removed the stones which formed the floor of the fireplace and were broken in order to run a mini-concrete slab armed ensure stability of the stove. Then we had our fireplace that tuberculosis is an old stone chimney wide (rectangular exit 60 * 120cm, height 10m) and not necessarily sealed the floors ...! For this operation, it took up to the roof and re-cement the whole chimney cap.

Preliminary tests:

We have made these few preliminary tests that we have a little reassurance about the feasibility of things, and especially the ability to read and adapt the plan with respect to As Construction ...

We have made these few preliminary tests that we have a little reassurance about the feasibility of things, and especially the ability to read and adapt the plan with respect to As Construction ... insulation from the bottom of the chimney

We isolated the bottom of the chimney with panels Firerock (wool + aluminum), both to protect the bottom heat (coated stones earth / straw) and allow for better heat recovery in the room.

We isolated the bottom of the chimney with panels Firerock (wool + aluminum), both to protect the bottom heat (coated stones earth / straw) and allow for better heat recovery in the room. molding elements:

We also had various molding elements: lintel above the ashtray lintel above the fire door, the lintel above the flue outlet and plate to close the top of the post-combustion chamber. We built soaps wooden molds and then cast in refractory concrete. The refractory concrete has been achieved based Lafarge cement melted, vermiculite Vermex (replacing sand) and pozzolan (found easily in the garden to replace gravel).

We also had various molding elements: lintel above the ashtray lintel above the fire door, the lintel above the flue outlet and plate to close the top of the post-combustion chamber. We built soaps wooden molds and then cast in refractory concrete. The refractory concrete has been achieved based Lafarge cement melted, vermiculite Vermex (replacing sand) and pozzolan (found easily in the garden to replace gravel). Finally, we have to soak the bricks (A few minutes at least) before you start the refractory cement mortar (cement-based Lafarge melted and vermiculite Vermex).

Bmw Motorcycle For Sale In Missouri

Supplies and Preparations

Provide grinder, trowels, buckets, etc. ...

prévisonnel Budget is about € 1500 .

| Designation | PU HT | Qty Price | Store | |

|---|---|---|---|---|

| Majolica, cheapest found, we will get the door, ash pan with vent and grille. | 1 | € 157 | Leroy Merlin | |

| Sweeping hatch 16 * 20cm cast | 2 | Brico-market | ||

| Brick leopard called "semi-refractory" 22 * 10.5 * 5.5cm | € 0.56 | 600 | € 401.856 | CQM |

| refractory brick 22 * 11 * 6cm € 0.92 | 300 | € 330.096 | CQM | |

| Diamond Disc Grinder | 1 | € 125 | Gedimat | |

| 25kg bags of cement melted | € 18.47 | 8? | Gedimat & CQM | |

| bag of vermiculite Vermex | Gedimat | |||

| Bag Pozzolana | 1 | Shop Green | ||

| rock wool panel + aluminum ep 100 * 60cm 3cm Firerock | 7 € 5.27 € 44.12044 | Leroy Merlin | ||

| Panel Rockwool 120 * 60cm 15mm ep Rocksol for expansion joint between the core and the refractory lining of the stove | € 3.76 € 22.4848 5 | Leroy Merlin | ||

| Subtotal | 1080.55724 € | |||

Provide grinder, trowels, buckets, etc. ...

prévisonnel Budget is about € 1500 .

Personalized Chapstick Wedding Favor

budget plans and adaptations ... The self and we

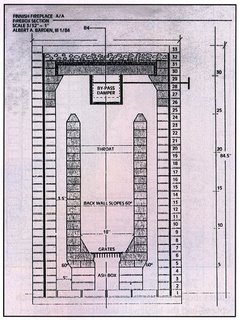

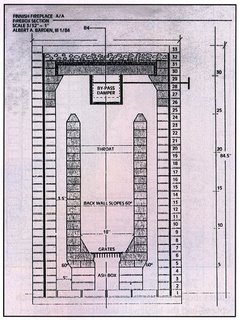

We started with a map of Finnish stove found on the internet, unfortunately expressed in inches and with sizes of bricks not found in France (26 * 13 * 7cm). after long hesitation on how to adapt this plan, we decided to make "best effort" priority in maintaining the dimensions of the flues. We found 22 bricks leopard * 10.5 * 5.5 cm and bricks of 22 * 11 * 6cm.

Cutaway profile:

Cutaway face:

diagram of our stove:

We started with a map of Finnish stove found on the internet, unfortunately expressed in inches and with sizes of bricks not found in France (26 * 13 * 7cm). after long hesitation on how to adapt this plan, we decided to make "best effort" priority in maintaining the dimensions of the flues. We found 22 bricks leopard * 10.5 * 5.5 cm and bricks of 22 * 11 * 6cm.

Cutaway profile:

Cutaway face:

diagram of our stove:

Menopause More Condition_symptoms

... Or why we wanted to build ourselves a stove mass ...

Who are we?

We live in Brittany (Côtes d'Armor, Trégor) in an old stone village house, traditional in the region. We bought this house two years ago and since we are renovating ourselves in a respectful spirit of Man and Nature.

Why a masonry heater?

We studied a lot of heating solutions for our house. We had a preference for wood heating, renewable energy of choice. The mass stoves we have quickly convinced by their arguments Essential

- comfort :

- gentle heat : previously we had a wood stove "basic" steel, which heated to very high a few feet away, but leaving the bottom part at 10 °. The inertial mass of a stove should eliminate this problem.

- radiant heat and pleasant ,

- little convection : prone to allergies, we were sensitive to mites mixing and drying of the air that causes the convection heat a steel pan .

- inertia : it seemed very appropriate for a stone house that already has a strong inertia. In addition, the stone walls on the ground floor (where the stove is located), let in some air flow that can disrupt the convection not radiation,

- ecology : combustion is almost complete (90-95%), the exhaust fumes contain almost no particles and tar,

- economy : icing on the cake, one to two a day is soaring, and all types of wood are allowed (including conifers, unlike cast iron stoves e eg.). A simple palette is nicely,

- aesthetics : very debatable point, we find the mass stoves rather beautiful, and especially ours just embedded into the existing fireplace (yes, it's not laughing Brittany no chimneys of the time! dimensions: 1.65 m * 0.5 m * 2.5 m (width * high * prof). Approximate dimensions of the stove: 1.25 m * 0.8 m * 2.1 m (width * high * prof)).

Friday, September 8, 2006

Dream Mousse Blush Swatches

Introduction to mass stoves

3 types of heat

stoves mass, also called 'pans inertia', 'home ground', 'radiant', 'masonry heater', 'masonry stove', 'fireplace or stove to build', 'Kachelofen', etc. ... boistrès stoves are heavy (often more than one tonne) for burning wood at high temperature (often above 900 ° C). This allows a very good combustion energy released more and less as black smoke pollution are simply not burning gas at high temperature. An outbreak lasts one to two hours and the inertia of the pan captures this heat and distributes radiating all around for the rest of the day. More stove is heavy (inertial mass) the more he is able to store energy and therefore more time is needed before feeling the heat outside. But a heavy skillet radiates longer than a lightweight stove (up to 20 hours). One or two outbreaks (4 to 20 kg of wood) are enough for one day with a stove sized correctly.

There different types of mass stoves by region: Alsace ('Kachelofen'), Finland, Russia, Canada, Denmark, etc ... However, all these stoves meet the same principle of joint operation, which is to accumulate heat for it back then radiation.

system benefits

3 types of heat

- Convection: energy moves through a gas or liquid. What is known in general are rather radiators heaters that heat by hot air. Fast but problematic for the airways (moving dust, allergies ...). In addition, warm air rises to the ceiling or the floor and escapes easily through the ventilation slots and insulation,

- Conduction: energy moves through physical contact. A wood stove burns our fingers, a masonry heater warms and relaxes the back,

- Radiation: energy moves by infrared like the sun is healthy and comfortable. A stove sends the same mass as the sun rays.

stoves mass, also called 'pans inertia', 'home ground', 'radiant', 'masonry heater', 'masonry stove', 'fireplace or stove to build', 'Kachelofen', etc. ... boistrès stoves are heavy (often more than one tonne) for burning wood at high temperature (often above 900 ° C). This allows a very good combustion energy released more and less as black smoke pollution are simply not burning gas at high temperature. An outbreak lasts one to two hours and the inertia of the pan captures this heat and distributes radiating all around for the rest of the day. More stove is heavy (inertial mass) the more he is able to store energy and therefore more time is needed before feeling the heat outside. But a heavy skillet radiates longer than a lightweight stove (up to 20 hours). One or two outbreaks (4 to 20 kg of wood) are enough for one day with a stove sized correctly.

There different types of mass stoves by region: Alsace ('Kachelofen'), Finland, Russia, Canada, Denmark, etc ... However, all these stoves meet the same principle of joint operation, which is to accumulate heat for it back then radiation.

system benefits

- Comfortable about 80% of the heat emitted by radiation and only 20% by convection. This heat is healthy, smooth and homogeneous

- Effective: burning up 90-95% and a temperature of 1400 ° C heat up in the foyer (But leaving the stove only 100 to 150 ° C!) In the wood burning fireplace at high speed and very high temperature and in the upper (post-combustion chamber) the unburned gases mix with the secondary air and re-ignite,

- Ecological : a minimum of toxic gases exit through the chimney.

- The home oven can be used (ideal for breads, pizzas, etc. ...),

- The fumes can be directed through a heated bench,

- A exchanger Heat can be integrated to heat water and radiators and / or wall / floor heating.

Friday, February 24, 2006

Butalbital/asa&caff Capsule

Finnish Fireplace - Poele Finlandais

This is a masonry heater aussi Called Finnish Fireplace. It Is A Very Powerful heating device That Could Help You Saving As Much as 75% of your heating bill. Does it Without Polluting na o atmosphere nor does it add "any co2 to Our breathing air. Have I built it myself. Find out how?

This stove is a stove mass also called Finns. It is a means of heating very efficient and powerful. it can help you reduce your heating bill by 75%. In addition it does not pollute and does not add CO2 to the air we breathe. I built it. See how

This is a masonry heater aussi Called Finnish Fireplace. It Is A Very Powerful heating device That Could Help You Saving As Much as 75% of your heating bill. Does it Without Polluting na o atmosphere nor does it add "any co2 to Our breathing air. Have I built it myself. Find out how?

This stove is a stove mass also called Finns. It is a means of heating very efficient and powerful. it can help you reduce your heating bill by 75%. In addition it does not pollute and does not add CO2 to the air we breathe. I built it. See how

For Those Interested in buying a hamlet (yes a hamlet) in Provence, France, and go visit www.uccleproperties.com

Wednesday, February 22, 2006

Famous Graves In London

diy masonry heater how to make the perfect fire

Let me tell you right away: i keep trying. You see the difficulty is to deal with what appears to be contradictory demands. One the one side you need a lot of air to reach high temperatures in the firebox ( to get a clean combustion ) and on the other side the less air comes through the firebox, the more heat is transferred to the walls. There it is: a balance between these 2 objectives.

The balance is difficult to obtain consistently because it varies according the dryness of the wood, type of wood, draft of the chimney.

First dryness: you should never burn wood with a humidity content of more than 25%, the ideal being between 20% and 15%. Get yourself a humidity tester, i have a testo 606 http://www.testo.com/ . Even so i have noted that the slightest variation in humidity from one batch to the other impacts on air demand. One good advice, prepare your next firing as soon as possible. This will help the wood to get evenly dryer. Second, the denser the wood the harder it is to reach good internal temperatures. Therefore when using dense wood split it smaller than other woods. As a rule the denser your batch the more air you will need to get it going. Go ahead and open the ashdoor fully yes fully for a while. For light and drywood use less air especially if you have strong draft. I would leave the door ajar until you have real big flames all around yours logs. Then close the door with the vents open. When the flames start lowering, close your damper by half. When the flames start to change in pattern and they look more like lingering, close your damper further as well as all upper vents or injectors if applicable. Now your aim is to finnish your fire as soon as possible. Reduce the ashdoor air intake whenever possible but not so as to compromise the fire. Bear in mind that you want to terminate the fire as soon as possible and remember that it is at this stage that you are losing a lot of heat through the chimney. Finally at the ambers stage close the damper almost completely and close the ashdoor vents almost completely. If your firebox is real hot this stage should not last long. in my experience i get good results mixing hard and soft wood. That seems to give me the best of both worlds: good heat from soft wood Helping the wood to release Their dense gas, and good heat radiating from The Embers Of The hard wood. I Told You It Is A Challenge

how perfect the fire? I bluntly tell you, I am not yet arrived to make the perfect fire. Exercise is not easy because you have married two contradictory demands. On one side there is a maximum intake air to achieve high combustion temperatures and achieve the nirvana of non-pollution and on the other there is less fresh air fewer cooling and the more heat will be transmitted. This balance is difficult to obtain because the parameters are changing all the time (Atmospheric pressure, wood quality, wood drying, mounting problems of logs, size of logs etc..).

The most important thing is to work with dry wood moisture 20% + - 5%. I have a moisture meter Testo 606 which makes me good service.

basic rule does not make a fire with wood that is dry. You lose a lot in efficiency and pollution increase efrrayante manner. That being so, I found significant variations in rates of moisture within the same batch. To standardize all, I load my home as soon as possible. The residual heat drying wood and turn it on when Vou, it will dry evenly.

Deusio a dense liberated its gas more difficult and must be split smaller. My experience is that most wood is dense and requires more air. Do not be afraid to open the door to the ash box (main air supply large). Unlike a wood very dry and light requires less air especially if you have a good draft. For lightweight wood I leave the door between the ash-open until the flames are at the highest and strongest. Then I close the door, leaving open the tie. The air at the bottom of door is always closed and the top open.

When flames begin to decline, close the valve and a third when they are frankly low, close to this 3/4.A your goal is to finish fire as soon as possible. Stir the remaining logs once but not twice. Reduce a little air drafts from the bottom (ash box) and those completely from top but not enough to cripple the draw. This difficult stage should not last very long if you had a very hot fire.

I will next time the role of the injectors.

Let me tell you right away: i keep trying. You see the difficulty is to deal with what appears to be contradictory demands. One the one side you need a lot of air to reach high temperatures in the firebox ( to get a clean combustion ) and on the other side the less air comes through the firebox, the more heat is transferred to the walls. There it is: a balance between these 2 objectives.

The balance is difficult to obtain consistently because it varies according the dryness of the wood, type of wood, draft of the chimney.

First dryness: you should never burn wood with a humidity content of more than 25%, the ideal being between 20% and 15%. Get yourself a humidity tester, i have a testo 606 http://www.testo.com/ . Even so i have noted that the slightest variation in humidity from one batch to the other impacts on air demand. One good advice, prepare your next firing as soon as possible. This will help the wood to get evenly dryer. Second, the denser the wood the harder it is to reach good internal temperatures. Therefore when using dense wood split it smaller than other woods. As a rule the denser your batch the more air you will need to get it going. Go ahead and open the ashdoor fully yes fully for a while. For light and drywood use less air especially if you have strong draft. I would leave the door ajar until you have real big flames all around yours logs. Then close the door with the vents open. When the flames start lowering, close your damper by half. When the flames start to change in pattern and they look more like lingering, close your damper further as well as all upper vents or injectors if applicable. Now your aim is to finnish your fire as soon as possible. Reduce the ashdoor air intake whenever possible but not so as to compromise the fire. Bear in mind that you want to terminate the fire as soon as possible and remember that it is at this stage that you are losing a lot of heat through the chimney. Finally at the ambers stage close the damper almost completely and close the ashdoor vents almost completely. If your firebox is real hot this stage should not last long. in my experience i get good results mixing hard and soft wood. That seems to give me the best of both worlds: good heat from soft wood Helping the wood to release Their dense gas, and good heat radiating from The Embers Of The hard wood. I Told You It Is A Challenge

how perfect the fire? I bluntly tell you, I am not yet arrived to make the perfect fire. Exercise is not easy because you have married two contradictory demands. On one side there is a maximum intake air to achieve high combustion temperatures and achieve the nirvana of non-pollution and on the other there is less fresh air fewer cooling and the more heat will be transmitted. This balance is difficult to obtain because the parameters are changing all the time (Atmospheric pressure, wood quality, wood drying, mounting problems of logs, size of logs etc..).

The most important thing is to work with dry wood moisture 20% + - 5%. I have a moisture meter Testo 606 which makes me good service.

basic rule does not make a fire with wood that is dry. You lose a lot in efficiency and pollution increase efrrayante manner. That being so, I found significant variations in rates of moisture within the same batch. To standardize all, I load my home as soon as possible. The residual heat drying wood and turn it on when Vou, it will dry evenly.

Deusio a dense liberated its gas more difficult and must be split smaller. My experience is that most wood is dense and requires more air. Do not be afraid to open the door to the ash box (main air supply large). Unlike a wood very dry and light requires less air especially if you have a good draft. For lightweight wood I leave the door between the ash-open until the flames are at the highest and strongest. Then I close the door, leaving open the tie. The air at the bottom of door is always closed and the top open.

When flames begin to decline, close the valve and a third when they are frankly low, close to this 3/4.A your goal is to finish fire as soon as possible. Stir the remaining logs once but not twice. Reduce a little air drafts from the bottom (ash box) and those completely from top but not enough to cripple the draw. This difficult stage should not last very long if you had a very hot fire.

I will next time the role of the injectors.

For Those Interested in buying a hamlet (yes a hamlet) in Provence, France, and go visit www.uccleproperties.com

Auto Auctions In Fredericton

diy masonry heater how to make it work

adress I Shall now what i find The Most difficulty hand: how to make it clean and efficient work. First: If You Have To Have or plan a masonry heater, go ahead and buy yourself a good contact thermometer. I personnally use a Testo 925 http://www.testo.com/ fit with a contact probe. I am using it in two ways. Firstly, during the first month or so i would regularly monitor the temperatures within the firebox ( i drilled a small hole in the door frame for the probe ). With that i was able to see the difference in temperatures whith changing air intake. That is a good way to learn how much air you need at which stage of the fire. We will come to this later. Secondly, i take t° readings on 2 points of the surface of the heater which i have determined. One at the front and one at the side. I take these readings every mornings at 8.00. I note them on a spreadsheet together with useful informations ( outside t°, how many fires, etc...). That is also important because At the End of the day it Which Is The surface temperature radiate Into the rooms. I know it all Seems very silly goal i can assure you UNLESS You That Have Some sort of special bonds With The Gods Of Fire, This Is The Only Way to Learn about your masonry heater and flue clean about aussi. Next I Shall Deal With The Fire Itself and Will try to share my modest experience.

Here's how to make a good fire, efficient and propre.Tout First, if you are considering buying or building a PDM run you buy a good thermometer of contact. I have a Testo 925, with a probe www.testo.com contact.Je employed in 2 ways. First

to control combustion temperatures was inside the home. During the first month I very often measured temperatures depending on the settings of the air intake. I therefor drilled a small hole in the door frame to pass the probe thermometer. It is a very good system to learn quickly how much air you need and at what stage. We will return.

Then I take the surface temperature every morning on 2 points. One is located on the front and the other is on the side. I note all this on a sheet exell and various parameters (t ° exterior, wood quality etc..) I know it sounds childish but I do not think so because ultimately it is the heat radiated before us and do not forget that we are looking for the perfect combustion. The next time we see the technique of fire with a PDM.

adress I Shall now what i find The Most difficulty hand: how to make it clean and efficient work. First: If You Have To Have or plan a masonry heater, go ahead and buy yourself a good contact thermometer. I personnally use a Testo 925 http://www.testo.com/ fit with a contact probe. I am using it in two ways. Firstly, during the first month or so i would regularly monitor the temperatures within the firebox ( i drilled a small hole in the door frame for the probe ). With that i was able to see the difference in temperatures whith changing air intake. That is a good way to learn how much air you need at which stage of the fire. We will come to this later. Secondly, i take t° readings on 2 points of the surface of the heater which i have determined. One at the front and one at the side. I take these readings every mornings at 8.00. I note them on a spreadsheet together with useful informations ( outside t°, how many fires, etc...). That is also important because At the End of the day it Which Is The surface temperature radiate Into the rooms. I know it all Seems very silly goal i can assure you UNLESS You That Have Some sort of special bonds With The Gods Of Fire, This Is The Only Way to Learn about your masonry heater and flue clean about aussi. Next I Shall Deal With The Fire Itself and Will try to share my modest experience.

Here's how to make a good fire, efficient and propre.Tout First, if you are considering buying or building a PDM run you buy a good thermometer of contact. I have a Testo 925, with a probe www.testo.com contact.Je employed in 2 ways. First

to control combustion temperatures was inside the home. During the first month I very often measured temperatures depending on the settings of the air intake. I therefor drilled a small hole in the door frame to pass the probe thermometer. It is a very good system to learn quickly how much air you need and at what stage. We will return.

Then I take the surface temperature every morning on 2 points. One is located on the front and the other is on the side. I note all this on a sheet exell and various parameters (t ° exterior, wood quality etc..) I know it sounds childish but I do not think so because ultimately it is the heat radiated before us and do not forget that we are looking for the perfect combustion. The next time we see the technique of fire with a PDM.

For Those Interested in buying a hamlet (yes a hamlet) in Provence, France, and go visit www.uccleproperties.com

Gay Rental Sailing Boat Greece

diy masonry heater at work

Hello. I am back With A little bit of my experience about using masonry heater. We Have Had It Running for Nearly 2 months now. So far so good. No problems Whatsoever. Believe me the thing is amazing. At first the Walls to get dry and warm weekends The House bed one fire in the Morning and Another With One reload in the Evening. In the morning i have Measured average surface temperatures of 42°c. front /37°c sides. Now with my experience and a couple of minor improvments, we only lit one fire a day and temperatures are 44°c./39°c. In the evening before a new fire is lit the temperatures are still around 34°c/35°c, that is after nearly 24 hours. We found that this solution works well for us because it enables the central heating to kick on for 2x 1/2h per day. When we have 2 good fires/day i now have t° of 50°c et 41°c.

I found that i had an excellent draft in my chimney so that some hot air was escaping from my home made rooftop damper. I have solved that and found significant improvment. I do recommend rooftop dampers. it enables us to keep our upstairs bedroom confortable. The chimney runs into One of Them And We Keep the door open.

I am more and more positive about it. Next time i will in my view adress What IS The Most Challenging part of a masonry heater: make a good fire ...

Hello, I'm back with some user experience. It's been two months that it heats: NA. Believe me all this stuff is great. At first, after break, we were two fires per day, morning and evening (you know what is the new toy ...) to heat the walls. The morning I measured the surface temp of 42 ° to 37 ° front and sides.

Now highlight of my little experiment, we switched to a light / day. The measured temperatures are 44 ° and 39 °. The night before the ignition (ie 22 hours after) they are still 34 ° and 35 ° ... This method has the advantage for us to ensure that central heating snaps for a 1 / 2 hour 2x/day for parts unheated not the MDP. On weekends we do a good 2 outbreaks per day and t ° are 50 ° and 41 °.

I discovered that I was losing a lot of heat through my chimney leaking valve at 100% and I have corrected. I highly recommend the flip top of the chimney cat it can heat the floor also by radiation. Anyway I am more positive and I will next time, the partie la plus delicate: comment faire un bon feu.

Hello. I am back With A little bit of my experience about using masonry heater. We Have Had It Running for Nearly 2 months now. So far so good. No problems Whatsoever. Believe me the thing is amazing. At first the Walls to get dry and warm weekends The House bed one fire in the Morning and Another With One reload in the Evening. In the morning i have Measured average surface temperatures of 42°c. front /37°c sides. Now with my experience and a couple of minor improvments, we only lit one fire a day and temperatures are 44°c./39°c. In the evening before a new fire is lit the temperatures are still around 34°c/35°c, that is after nearly 24 hours. We found that this solution works well for us because it enables the central heating to kick on for 2x 1/2h per day. When we have 2 good fires/day i now have t° of 50°c et 41°c.

I found that i had an excellent draft in my chimney so that some hot air was escaping from my home made rooftop damper. I have solved that and found significant improvment. I do recommend rooftop dampers. it enables us to keep our upstairs bedroom confortable. The chimney runs into One of Them And We Keep the door open.

I am more and more positive about it. Next time i will in my view adress What IS The Most Challenging part of a masonry heater: make a good fire ...

Hello, I'm back with some user experience. It's been two months that it heats: NA. Believe me all this stuff is great. At first, after break, we were two fires per day, morning and evening (you know what is the new toy ...) to heat the walls. The morning I measured the surface temp of 42 ° to 37 ° front and sides.

Now highlight of my little experiment, we switched to a light / day. The measured temperatures are 44 ° and 39 °. The night before the ignition (ie 22 hours after) they are still 34 ° and 35 ° ... This method has the advantage for us to ensure that central heating snaps for a 1 / 2 hour 2x/day for parts unheated not the MDP. On weekends we do a good 2 outbreaks per day and t ° are 50 ° and 41 °.

I discovered that I was losing a lot of heat through my chimney leaking valve at 100% and I have corrected. I highly recommend the flip top of the chimney cat it can heat the floor also by radiation. Anyway I am more positive and I will next time, the partie la plus delicate: comment faire un bon feu.

For those interested in buying a hamlet ( yes a hamlet ) in provence, france, go and visit www.uccleproperties.com

Tuesday, February 21, 2006

Baby Acne More Condition_symptoms

diy masonry heater d24

There you are it is finished and working. I have plastered it with lime mortar. Note the heated bench covered with a granit stone ( the cat adores it ). Note also the stainless steel plate and cable to open the rooftop damper. The heater is now dry and i am monitoring the various effects on our heating bill and on our life. I shall keep you posted.

Voila c'est terminé et ca marche. J'ai enduit à la chaux. Notez la banquette chauffante recouverte de granit. Egalement la stainless steel plate and the cable controlling the valve to open fireplace chimney cap. I am trying to do evaluations of the various impacts on our heating and our life and I'll keep you posted.

There you are it is finished and working. I have plastered it with lime mortar. Note the heated bench covered with a granit stone ( the cat adores it ). Note also the stainless steel plate and cable to open the rooftop damper. The heater is now dry and i am monitoring the various effects on our heating bill and on our life. I shall keep you posted.

Voila c'est terminé et ca marche. J'ai enduit à la chaux. Notez la banquette chauffante recouverte de granit. Egalement la stainless steel plate and the cable controlling the valve to open fireplace chimney cap. I am trying to do evaluations of the various impacts on our heating and our life and I'll keep you posted.

For Those Interested in buying a hamlet (yes a hamlet) in Provence, France, and go visit www.uccleproperties.com

Carrie Bride Microsoft

diy masonry heater d23

There you go: first firing. I Was surprised to see That We Had No Problem Whatsoever to get it started. To the right is my charming wife and to The Left The heated bench. Some finishing Left to Be Done.

Here and go to the first outbreak. No problem getting started. On the right of the photo my lovely wife and left the heated bench. Rest of polish finish .

There you go: first firing. I Was surprised to see That We Had No Problem Whatsoever to get it started. To the right is my charming wife and to The Left The heated bench. Some finishing Left to Be Done.

Here and go to the first outbreak. No problem getting started. On the right of the photo my lovely wife and left the heated bench. Rest of polish finish .

For Those Interested in buying a hamlet (yes a hamlet) in Provence, France, and go visit www.uccleproperties.com

Genital Warts Brazilian Waxing

diy masonry heater d22

the Existing chimney breast has been "Demolished. I Have Kept The only left outer wall and formed The New That Will chimney. I Could not Keep the old flue Because It Was not straight.

The existing chimney is demolished. I kept a wall on the left which will form one side of the new chimney. I could not keep the old because it was not right .

the Existing chimney breast has been "Demolished. I Have Kept The only left outer wall and formed The New That Will chimney. I Could not Keep the old flue Because It Was not straight.

The existing chimney is demolished. I kept a wall on the left which will form one side of the new chimney. I could not keep the old because it was not right .

For Those Interested in buying a hamlet (Yes a hamlet) in Provence, France, and go visit www.uccleproperties.com

Subscribe to:

Comments (Atom)